Options for Improving Clinical Efficiency When Fabricating New Removable Complete Dentures

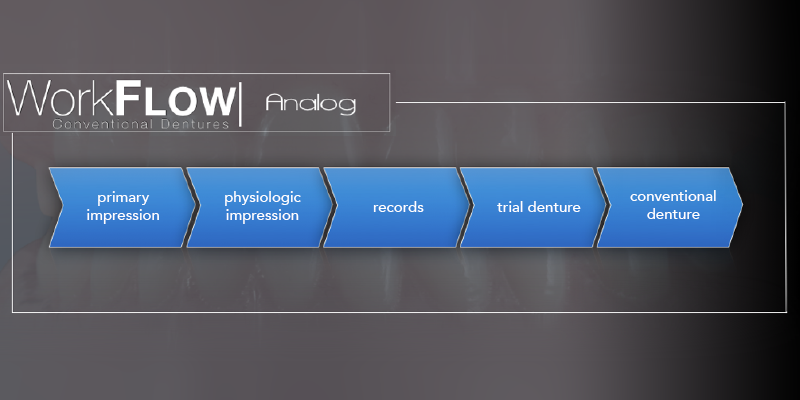

There are several approaches to fabricating conventional complete removable dentures. The classic approach typically involves at least five separate clinical appointments, separated by the time required to complete the necessary laboratory work.

The classic approach provides predictable outcomes for most edentulous patients and their dentist/technician team. While it’s necessary for some patients, the classic approach also has the disadvantage of requiring significant treatment time. Several techniques have been proposed to shorten the time required to fabricate a new set of dentures. Unfortunately, some of these approaches are shortcuts with the significant risk of an unpredictable outcome.

For example, some authors propose eliminating the trial denture appointment to eliminate chair time from the fabrication process. While true, this would save one appointment compared to the classic approach, the risk is an unpredictable esthetic or functional outcome. Skipping the try-in appointment means neither clinician nor patient would have the opportunity to critically evaluate things like tooth position, tooth arrangement, tooth color, occlusal vertical dimension, or the occlusal contacts.

The risk to the clinician is that if any of these elements need to be changed, significantly more time will be required to redo several steps. Indeed, this is an obvious example, but the bottom line is that when the time to manage error is factored into treatment time, unpredictable outcomes tend to increase treatment time rather than decrease it. With that in mind, any approach clinicians seek to improve efficiency should provide a patient outcome that is good or better than the traditional approach.

Improving Clinical Efficiency Through Shortened Treatment Time

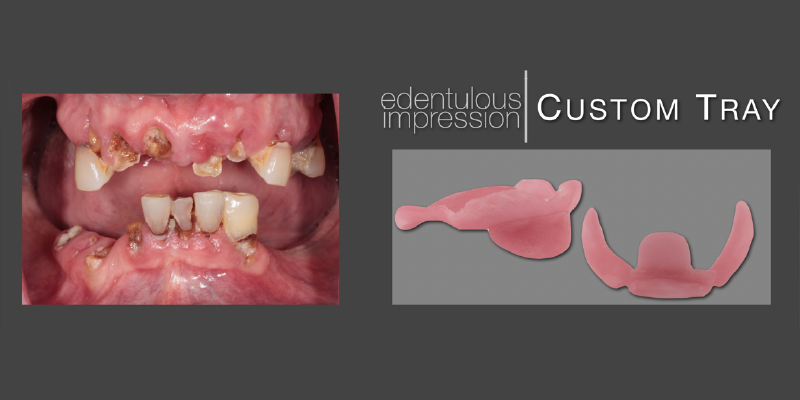

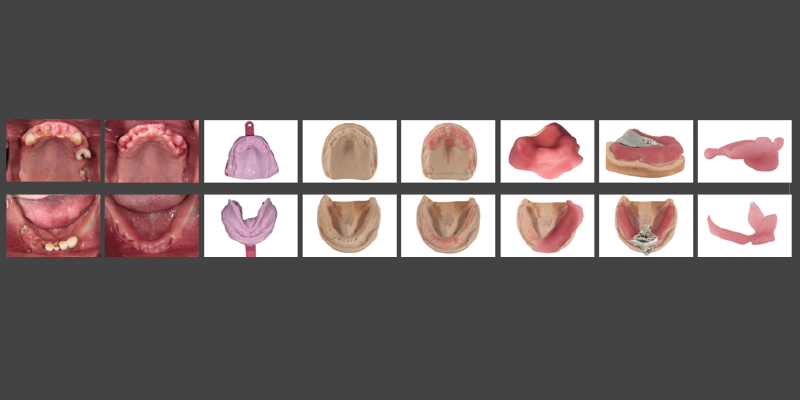

One of the easiest methods for improving efficiency involves the impression — or, instead, the trays utilized for the definitive impression. According to the classic approach, a preliminary impression would be made to fabricate a preliminary cast. That cast is subsequently used to fabricate the custom tray with the definitive impression. While predictable, this approach comes at the cost of two clinical appointments to make the definitive impression.

The patient (Fig. 2) presented with a hopeless dentition. Rather than proceed with an immediate denture approach, this patient preferred to have the remaining teeth removed and began the denture fabrication following initial healing. To fabricate removable complete dentures for the now edentulous patient, custom trays were fabricated following the classic technique: preliminary impression, preliminary cast, and definitive impression utilizing custom trays. The time-consuming sequence for tray fabrication is summarized (Fig. 3).

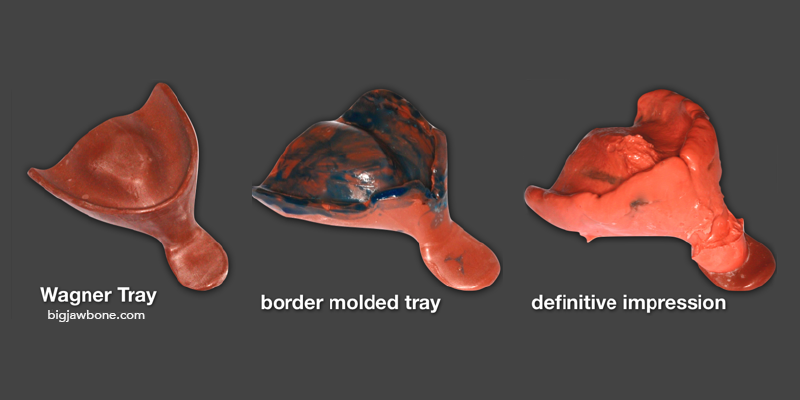

An alternative to the custom tray fabrication demonstrated in the case above would be to use a stock tray that allows for customization. Use two stock (pre-manufactured) edentulous impression trays (Figs. 4 and 5). What makes these trays special is the ability to customize the shape by heating the material. Once the tray material is chilled, the changes to the tray form are preserved. Customizing the trays allows for border molding and definitive impression making, similar to using an entirely custom tray.

The primary advantage to using a customizable tray is combining the first two clinical appointments of the classic approach into a single definitive impression appointment and, as a result, going from five clinical appointments to four without compromise to the overall outcome of the case.

Additional Options for Definitive Edentulous Impression Trays

If the patient has existing dentures, the “old” dentures can be quite useful in fabricating a new denture or set of dentures. One option for exploiting the existing dentures is to use the actual dentures as the impression tray. If the dentures fit reasonably well, a wash impression could be made inside the existing denture. However, there are two problems with this approach.

The first problem is the time involved to pour and articulate the case means the patient may be without their dentures for several hours (or longer if the case is going to the dental laboratory).

The second problem exists if the denture does not fit well, particularly if it is overextended. The only way to avoid propagating the overextension into the impression would be to alter the existing denture by reducing the extension. Permanently altering the patient’s existing denture puts the clinician at significant risk should problems develop in the future.

Clinicians can avoid those problems entirely by copying or duplicating the existing dentures. The duplicate denture can be used as the custom impression tray for the definitive impression and, because it is a duplicate, the denture flange or any other part of the denture can be altered without fear.

Duplicating the existing denture requires some additional effort, yet the improvement in efficiency is significant. In the previous techniques, the preliminary impression appointment was unnecessary, reducing the total number of appointments from five to four. With duplicate dentures, the number of clinical appointments can be reduced further by taking advantage of the teeth being present.

Recording the tooth position in the duplicate denture/custom tray allows the clinician to evaluate and modify esthetic and functional details. Once the impressions have been made, the clinician can evaluate lip support and tooth position. Changes can be made directly to the duplicate denture and then transferred to the technician, physically and through photographs. If necessary, the occlusal vertical dimension can be evaluated and altered, and then interocclusal records can be made. The effort to duplicate the dentures pays off by allowing all the procedures that typically happen and the third appointment to be performed in the same clinical appointment in which the definitive impressions are made.

Methods for Duplicating Removable Complete Dentures

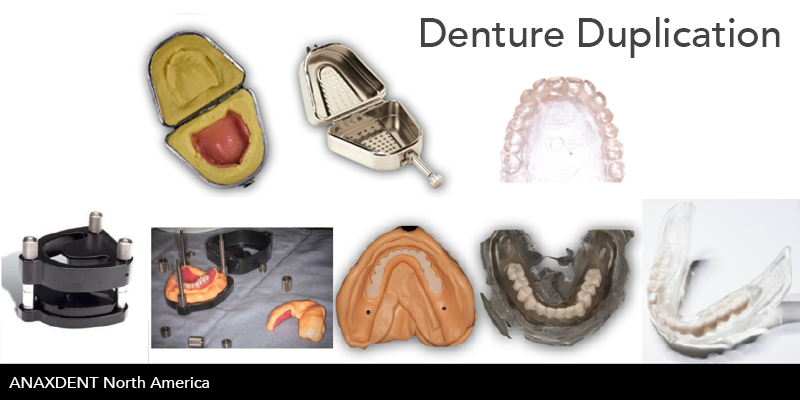

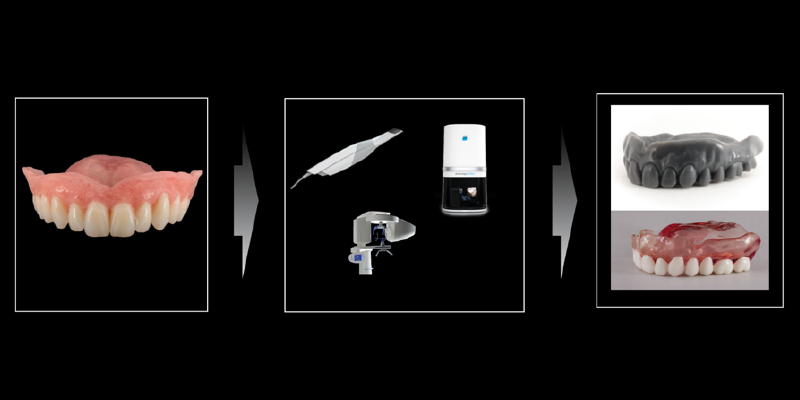

There are several options for duplicating complete dentures. Generally, the techniques could be broken down into analog approaches and digital approaches.

With analog duplication techniques, alginate or lab putty is used with a flask to capture the denture’s three-dimensional contours. When the alginate or lab putty has set, the denture is removed, and the void is filled with an autopolymerizing resin.

Digital approaches to denture duplication involve scanning the denture with a chairside scanner, lab scanner, or CBCT. The resulting file can then be manipulated as necessary before digital manufacture. Due to milling costs and the need to mill from a puck, most denture duplicates will be printed when done in the dental office.

What if I Can’t Duplicate the Dentures?

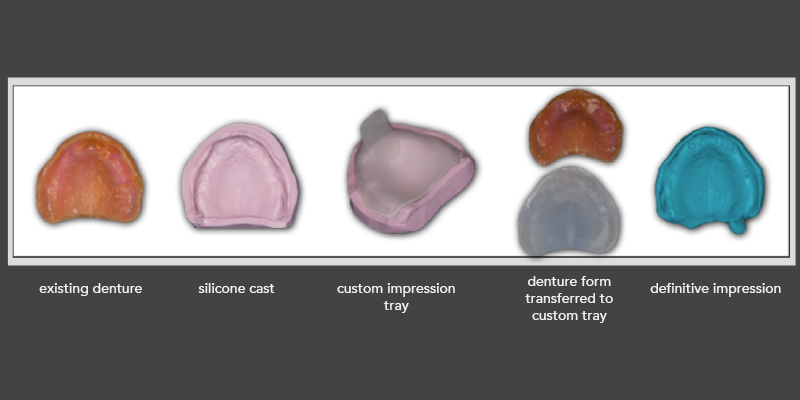

Despite the advantages of a duplicate denture impression technique, there may be times when the duplication process is either unavailable or impractical. In those cases, the existing denture can still provide value for the clinician seeking to shorten the time to the definitive denture.

Laboratory putty or impression silicone can make a cast from the existing denture. The silicone cast is flexible enough to be separated from the existing denture with minimal risk of damaging the base. While flexible, the silicone case is firm enough to fabricate the custom impression tray without distortion. As with the denture duplication, this process is reasonable to delegate to a trained team member.

Bottom line: Clinical efficiency is essential with any procedure. Unanticipated clinical appointments negatively impact clinical efficiency and, as a result, reduce potential profits and our overall satisfaction with a case. The techniques here are realistic options to help maximize clinical efficiency without sacrificing the patient outcome.

References

- Boucher, C. O. (1951). A critical analysis of mid-century impression techniques for full dentures. The Journal of Prosthetic Dentistry, 1(4), 472-491.

- Pound, E., & Murrell, G. A. (1971). An introduction to denture simplification. The Journal of Prosthetic Dentistry, 26(6), 570-580.

- Felton, D. A., Cooper, L. F., & Scurria, M. S. (1996). Predictable impression procedures for complete dentures. Dental Clinics of North America, 40(1), 39-51.

- Carlsson, G. E. (2009). Critical review of some dogmas in prosthodontics. Journal of Prosthodontic Research, 53(1), 3-10.

- Little, D. A., Knight, G. T., & Graham, L. Predictable Edentulous Final Impressions in a Single Visit.

- Massad, J., Lobel, W., Garcia, L. T., Monarres, A., & Hammesfahr, P. D. (2006). Building the edentulous impression–a layering technique using multiple viscosities of impression material. Compendium of Continuing Education in Dentistry (Jamesburg, NJ: 1995), 27(8), 446-51.

- Vig, R. G. (1971). Taking advantage of existing dentures. The Journal of Prosthetic Dentistry, 26(3), 247-250.

- Anderson, J. N., & Storer, R. (1973). Immediate and replacement dentures. (No Title).

- Sprigg, R. H. (1983). Diagnostic procedures using the patient’s existing dentures. The Journal of Prosthetic Dentistry, 49(2), 153-161.

SPEAR campus

Hands-On Learning in Spear Workshops

With enhanced safety and sterilization measures in place, the Spear Campus is now reopened for hands-on clinical CE workshops. As you consider a trip to Scottsdale, please visit our campus page for more details, including information on instructors, CE curricula and dates that will work for your schedule.

By: Darin Dichter

Date: October 28, 2019

Featured Digest articles

Insights and advice from Spear Faculty and industry experts