Need Smoother Preps?

As we all know, the smoother we make our preparations — especially in regard to indirect restorations — the better.

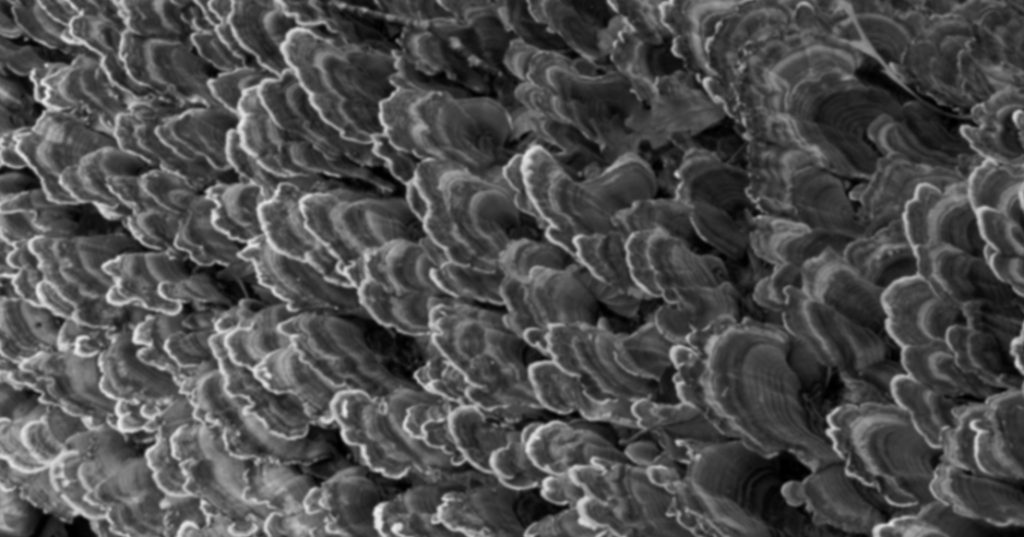

Smooth preparations not only facilitate easier and better fabrication, they also result in increased long-term predictability of our restorations. While any restoration benefits from a smooth preparation, with the increased use of all porcelain restorations and CAD/CAM, the need for smooth restorations has never been more critical.

Two of the simplest and most cost-effective ways we can improve the smoothness of our preparations is to take a look at the burs or cutting instruments we’re using and the handpieces that we use to drive them. The three instruments I’ve found most easy to use, particularly for margin refinement, are fine-grit, flat-ended modified-cylinder diamonds, a fine-grit, round-ended cylinder diamond bur, or a pointed friction grip on which the point on the stone has been removed (essentially converting it to a modified cylinder stone).

Keep in mind there is a hidden danger when using any one of these instruments that will be disastrous if not appropriately managed. The danger is carrying the bur too far laterally onto the tooth, which will result in the “up-curve” of the bur cutting a sharp lip at the edge of your margin, which will make it very difficult if not impossible to fabricate an excellent-fitting restoration.

To avoid this, if you’re using a flat-ended modified cylinder, make sure to use the flat apical end of the instrument, which will mean that a small portion of the bur will be hanging off the tooth and toward the soft tissue. If using a round-ended cylinder bur, you must use only slightly less than half the diameter of the bur on your margin.

Equally if not even more critical is the handpiece used to drive your instrument of choice. While our high-speed handpieces are great for efficient initial preparation, they’re far from the best at allowing us to achieve the smoothest final preparation. For that, we really need much slower handpieces that provide a better tactile feel. The most ideal handpiece, or at least my favorite, is a 1:1 attachment for my electric motor.

Another option with less of an initial investment (especially if you’re not yet using electric motors) is a friction grip attachment for your slow-speed air motor. When using either of the burs listed above for your final margin refinement, it’s best to move the bur in one constant direction around the tooth, rather than in a back-and-forth motion, as the latter will inadvertently leave small steps in your margin preparation. Lastly, place a finger from your opposite hand to help balance and steady your movement around the tooth.

FOUNDATIONS MEMBERSHIP

New Dentist?

This Program Is Just for You!

Spear’s Foundations membership is specifically for dentists in their first 0–5 years of practice. For less than you charge for one crown, get a full year of training that applies to your daily work, including guidance from trusted faculty and support from a community of peers — all for only $599 a year.

By: John Carson

Date: December 14, 2017

Featured Digest articles

Insights and advice from Spear Faculty and industry experts