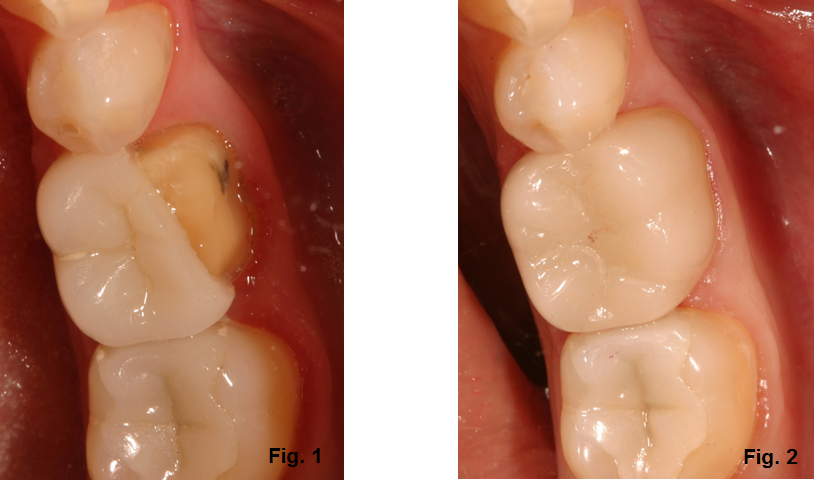

Ceramic Restorations: Why Do They Break?

All ceramic restorations can break, even IPS e.max lithium disilicate, which has a flexural strength of 400 mPa. The two most common reasons for ceramic restoration failure are:

- Microcracks that are created in the ceramic restoration at the time of occlusal adjustment. Using a diamond or stone that is too coarse or at too high of an RPM speed, will cause excessive trauma, vibration, and heat, which cause the microflaws. The ceramic restoration may fracture immediately at the time of adjustment or cracks will propagate over time, which will ultimately cause chipping or catastrophic failure of the restoration.

- When the ceramic restoration is thinner than manufacturer recommendation, cracking, chipping or fractures can occur. Ivoclar recommends the following thickness be maintained to minimize the risk of failure:

- A minimum of 1.5 mm thickness in the central groove and cusp tips for onlays and crowns.

- A 1.0 mm shoulder preparation with a rounded internal line angle for crowns.

Additional causes of ceramic restoration failure are:

- Microcracks are created in the ceramic at the time of fabrication due to improper handling, grinding, or polishing. This may occur in the laboratory or during chairside milling.

- Inaccurate internal fit of the restoration (between the restoration and the tooth), which causes high spots where pressure during try-in or seating can cause ceramic trauma. The high spots may be caused by:

- Inaccurate scanning/impressing

- Inaccurate margin trimming

- Inaccurate milling

- Adjusting of the ceramic during fitting on the die or tooth

- Abrasion of the die material resulting in an improper fit of the ceramic on the tooth

- Excessive occlusal load applied at the time of try-in to check occlusion or during the cementation process.

You should always handle ceramic restorations with care during every stage of the fabrication, try-in, or insertion process. The techniques to use for adjustment and polishing will be discussed in my next article.

FOUNDATIONS MEMBERSHIP

New Dentist?

This Program Is Just for You!

Spear’s Foundations membership is specifically for dentists in their first 0–5 years of practice. For less than you charge for one crown, get a full year of training that applies to your daily work, including guidance from trusted faculty and support from a community of peers — all for only $599 a year.

By: Robert Winter

Date: October 2, 2014

Featured Digest articles

Insights and advice from Spear Faculty and industry experts