Tips on Fabricating Implant Provisionals and Custom Healing Abutments

As I discussed in a previous article, custom healing abutments and implant provisionals can be a vital tool in influencing the soft tissue healing around implants.

In this article, I will cover some tips on fabricating both screw-retained implant provisionals and custom healing abutments. For much of this article, I’ll focus the detail on making implant provisionals due to the fact that fabricating a custom healing abutment is very similar in many ways.

Steps to fabricating implant provisionals and custom healing abutments

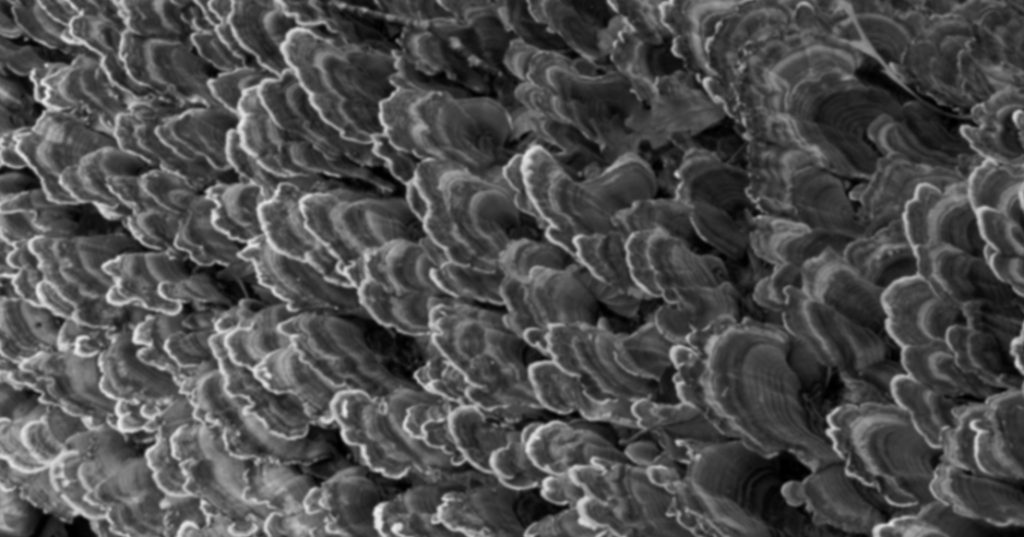

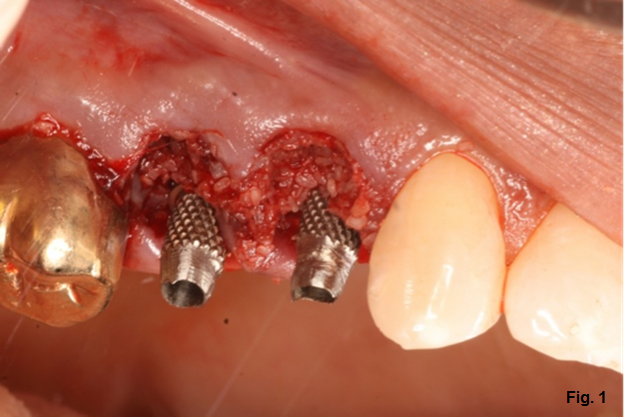

The first step is to start with an implant temporary abutment. These are typically long, narrow cylinders made of plastic or metal (Fig. 1) that you add material to achieve your desired form. Both the plastic and metal versions have their positives and negatives; I generally prefer the metal versions when available because they’re thinner and give me more room to work. The big downside to the metal versions is the fact that their color can bleed into your provisional.

The second step when it comes to fabricating implant provisionals is to tack your provisional shell to the temporary abutment or abutments. It’s worth noting that this shell can be made in many different things, including a hollowed-out denture tooth, a shell temporary or even by hollowing out the patient’s old crown. Simply make a hole through the top of whatever you’re using that will allow the temporary abutment to pass through it. Once you have the shell properly positioned, lute it in place with composite. I will typically do this by injecting flowable composite from the occlusal, being careful not to get any resin in the screw access hole. I usually will cover the screw with cotton just to be sure I keep it completely clean. Once you have it secured on the implant, or implants, it should look something like Fig. 2.

It’s important to note that the only goal here is to fix the shell to the temporary abutment. We, in fact, are not worried about creating the emergence profile at this point and if we are doing this step in the mouth, it can also be done on a model; we do NOT want get even close to allowing material into the tissue area.

The next step is to establish the emergence profile of the implant provisional. This is done by simply adding composite (flowable and/or paste) until you have achieved your desired contours as pictured in Fig. 3.

It’s important to note that this step should be done extraorally to prevent getting any debris into the surgical site.

When it comes to the custom healing abutments, you can really skip right to the above step, fabricating only the gingival portion of an implant provisional. Just make sure to extend the composite slightly above the tissue level so you’re supporting all of the tissue you need to influence.

If you’re like me, when you read about doing something you’ve never done before, you will want to actually do this hands-on before ever doing it on a patient. The good news is, Spear has workshops that offer hands-on experience. If that sounds like something you would like, contact one of our education advisors and they can direct you to the right class for you.

SPEAR campus

Hands-On Learning in Spear Workshops

With enhanced safety and sterilization measures in place, the Spear Campus is now reopened for hands-on clinical CE workshops. As you consider a trip to Scottsdale, please visit our campus page for more details, including information on instructors, CE curricula and dates that will work for your schedule.

By: John Carson

Date: May 28, 2018

Featured Digest articles

Insights and advice from Spear Faculty and industry experts