Steps for Fabrication of an Implant-Supported Prosthesis

Fabrication of a full-arch, implant-supported prosthesis is one of the most challenging clinical and technical procedures in dentistry.

Completing all steps in this sequence is essential to have predictable fit, esthetic, and functional outcomes. If individual steps are skipped or imprecise, the clinician is at risk of challenges during insertion of the final prosthesis or a significant remake because of compromises.

Following these steps during the fabrication process for the final prosthesis will facilitate a predictable outcome. These steps are only applicable if the implants are positioned with a common path of insertion. If they don’t share a common path of insertion, it’s almost impossible to create a single prosthesis.

Step 1

Screw open-tray impression copings onto the implants. Connect all the implant copings together with GC Pattern Resin or similar material. Take an open-tray, fixture-level impression. Make certain soft tissue detail is the same as taking a denture impression. See this video for more on impression copings and techniques.

Step 2

Send the impression to the laboratory to make the initial cast that will be used to fabricate a verification jig to confirm accuracy of the impression and cast, and for initial jaw relation records.

Step 3

Use the verification jig to check the accuracy of the impression and master cast. If it doesn’t fit precisely and seat passively, cut the jig into segments, screw it onto the implants, and reconnect it with GC Pattern Resin. A new master cast will need to be made. Second, a wax rim placed onto this jig is used exactly like a base plate used when fabricating a denture. Using the wax rim, establish the ideal anterior tooth length, labial position for lip support, occlusal plane, vertical dimension, and midline.

Step 4

Take a face bow transfer and bite registration record in CR at the vertical dimension of occlusion. Take an impression of the mandibular arch with a polyvinyl impression material. (Spear members, check out this video for more on vertical impression considerations.)

Step 5

Return all items to the lab. The lab mounts the casts. A diagnostic wax-up of the teeth and soft tissue is completed as needed. A simple bis-acryl try-in prosthesis is fabricated based on the wax-up. An alternative technique is placing denture teeth on the verification jig, which represent the desired tooth form and soft tissue (pink wax). Either technique establishes the desired anterior and posterior tooth position, occlusal plane, vertical dimension, and occlusion (similar to a wax try-in for a complete denture).

Step 6

Try to confirm anterior tooth length, form, arrangement, midline, occlusal plane, vertical dimension, and occlusion in the initial bis-acryl prosthesis. Make any necessary adjustments. Portrait photographs are taken of the patient in repose, maximum smile, and an image with anterior teeth parted by 1–2 mm using lip retractors. Return all items to the lab.

Step 7

A provisional prosthesis is inserted for one to two months to guide soft tissue around the abutments and confirm the esthetics and function. After everything is deemed acceptable, portrait photos are taken with the patient in repose, maximum smile, lips retracted, and teeth parted by 1–2 mm. The lab fabricates a provisional prosthesis based on the desired changes (if any) from the initial try-in prosthesis. If no changes are made, the initial bis-acryl try-in prosthesis may be used for the provisional prosthesis.

- If the initial bis-acryl prosthesis is going to be used as the provisional prosthesis, clear communication with the technician is critical so the initial prosthesis will be fabricated appropriately.

- Please keep in mind that if significant changes need to be made to the more substantially crafted prosthesis once the try-in is completed, a new provisional will need to be fabricated, and you will incur increased costs to do so (compared with having both an initial and provisional prosthesis made).

Step 8

Take an impression of the provisional for “go by” information. Take a bite registration record if there is inadequate anatomy to hand articulate the cast. The cast of the provisional will be mounted to the already mounted opposing cast.

Step 9

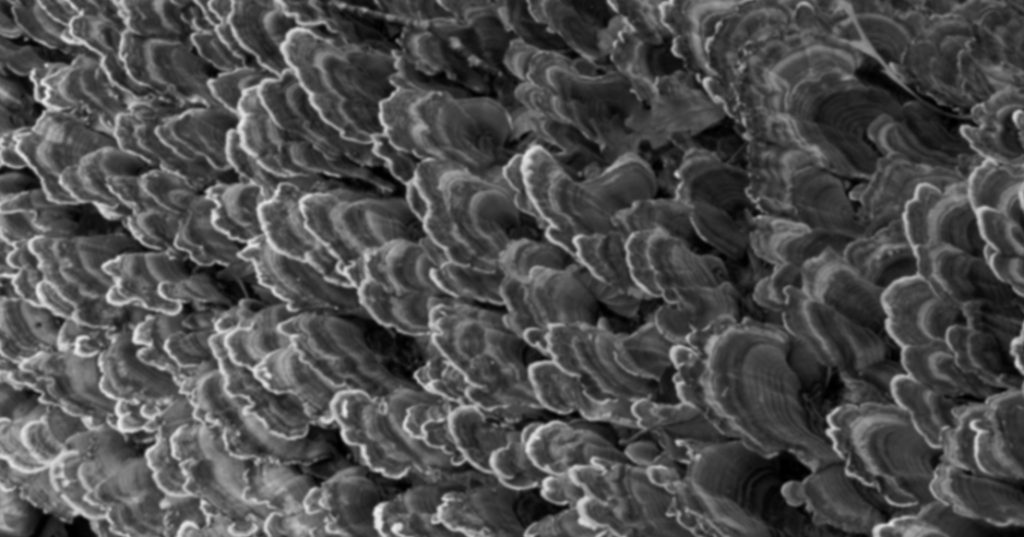

Custom impression copings are fabricated for each implant site and used to accurately transfer the new soft-tissue contours. Connect all the impression copings with GC Pattern Resin and take an open-tray, fixture-level impression. Make sure the soft-tissue detail is the same as taking a denture impression. Send all items to the lab.

- If the head of the implants is minimal subgingival (1–2 mm) and there is no soft-tissue manipulation with the provisional prosthesis, a new impression is not necessary.

Step 10

If a new impression is taken, the laboratory pours the impression to make the master soft tissue cast. The laboratory fabricates a verification jig to confirm the accuracy of the impression.

Step 11

The clinician does a try-in of the verification jig. It must fit accurately and passively. Return to the lab. If it does not fit accurately and passively, the clinician will section and reconnect it intraorally with GC Pattern Resin.

Step 12

The clinician screws the provisional onto the master cast and mounts it on the articulator by hand or with the bite registration that was taken. Now the master cast and cast of the provisional are mounted to the same opposing cast.

Step 13

The lab fabricates the metal framework. If the verification jig was sectioned, a new cast will need to be fabricated and remounted before the metal framework is made.

Step 14

The clinician does the try-in of the metal framework. It must fit accurately and passively. Return to the lab. If it does not fit accurately and passively, the framework is cut, and the segments are screwed into position using GC Pattern Resin and reconnected. A new cast will need to be made. The laboratory will have to solder the bridge. Another try-in is advised after soldering.

Step 15

The chosen ceramic is applied to framework and returned to the clinician for a bisque-bake try-in. It’s critical that the casts (wax-up, provisional and master) are cross-mounted, so the provisional cast can be used to determine tooth position, occlusal plane and occlusion.

Step 16

The clinician does a try-in of the bisque-bake prosthesis. Confirm tooth esthetics, pink esthetics, and occlusion. Return to the lab.

Step 17

The final glazing of the ceramic is completed by the laboratory and returned to the clinician.

Step 18

The clinician inserts the definitive prosthesis.

Be certain to schedule enough clinical time for each appointment, and to not overpromise a timeline for completion because of the complexity of the process and the potential that extra steps or appointments may be necessary.

Following these essential steps will significantly increase the predictability of the fit, esthetics, and function of the screw-retained, implant-supported prosthesis.

VIRTUAL SEMINARS

The Campus CE Experience

– Online, Anywhere

Spear Virtual Seminars give you versatility to refine your clinical skills following the same lessons that you would at the Spear Campus in Scottsdale — but from anywhere, as a safe online alternative to large-attendance campus events. Ask an advisor how your practice can take advantage of this new CE option.

By: Robert Winter

Date: March 19, 2018

Featured Digest articles

Insights and advice from Spear Faculty and industry experts