New Invention May Help the Body Generate New Bone

According to a recent news release, a new invention made at the Faculty of Dentistry, University of Oslo, Norway, helps the body generate new bone that’s as strong as the original. Using this new method, dentists can insert artificial scaffolding that will determine where the new bone tissue will grow.

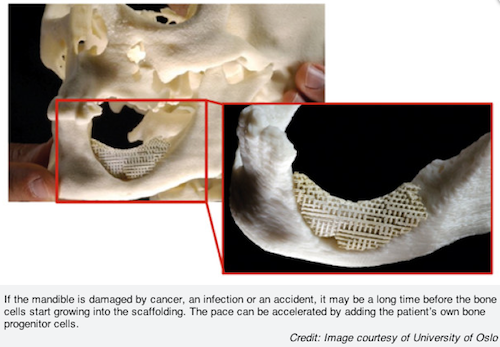

If there’s too wide a gap between two bone fragments, or if parts of the bone have been damaged, the body doesn’t always succeed in repairing the damage by itself, as can happen when some of the bone has been removed during cancer surgery or when the bone has been damaged by radiotherapy.

“This is where our invention comes in,” says Ståle Petter Lyngstadaas, research dean at the Institute of Biomaterials, Faculty of Dentistry. Along with professor Jan Eirik Ellingsen, associate professor Håvard Jostein Haugen and others, Lyngstadaas has developed and patented an artificial scaffolding that helps the body to repair such “critical” damage.

“With our new method, it’s sufficient to insert a small piece of synthetic, bone-stimulating material into the bone. The artificial scaffolding is as strong as real bone, yet porous enough for bone tissue and blood vessels to grow into it and work as a reinforcement for the new bone.”

If the defect is major, the bone cells will take a long time to grow into the scaffolding. “To speed things up, we can take bone progenitor cells or bone marrow that contain committed stem cells from the patients and insert them into the scaffolding,” Haugen said. “This will cause the process to accelerate.

“When bone needs to be built into defects where the distance between the bone fragments exceeds 1 cm or so, stem cells should be added to obtain a good result, but stem cells are normally not required to solve problems with loose teeth and periodontitis.”

The bone cells are dependent on nutrients, good growth conditions, and a specific signal to differentiate into bone-forming cells. “One must therefore ensure that the surrounding bone tissue is healthy, and that there is ample blood supply to the site of surgery,” he says.

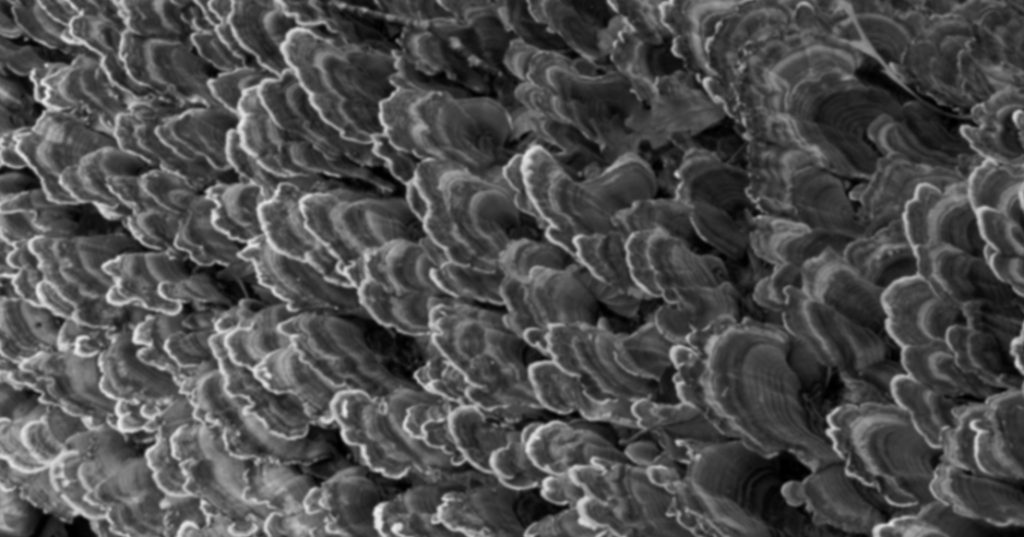

According to the authors, manufacturing the material is a simple matter. A mixture of water and ceramic powder made of medical-grade titanium dioxide nanoparticles is poured through ultrapure foam rubber designed to look like trabecular bone. When the mixture has solidified, it’s heated to a temperature that causes the foam rubber to dissolve into water vapor and carbon dioxide, and the nanoparticles ligate into one solid structure. The result is a mirror image of the foam rubber structure.

The Norwegian dentists have tested the new method successfully on rabbits, pigs, and dogs. In 2014, they want to undertake clinical studies on patients with periodontitis and damage to the mandibular bone. To establish which method works best, it is advantageous to perform tests on patients with periodontitis in particular.

SPEAR STUDY CLUB

Join a Club and Unite with

Like-Minded Peers

In virtual meetings or in-person, Study Club encourages collaboration on exclusive, real-world cases supported by curriculum from the industry leader in dental CE. Find the club closest to you today!

By: Cody Lopez

Date: March 20, 2014

Featured Digest articles

Insights and advice from Spear Faculty and industry experts