Getting the SRA Abutment Right in Implant-Supported Restorations

By Ricardo Mitrani on December 20, 2022 | 2 commentsA common and integral component in the fabrication of an implant-supported fixed dental prosthesis or fixed hybrid prosthesis is the “SRA abutment”—also known as the transmucosal abutment. This component is designed to provide two key features:

- Elevating the platform of the implant by bringing the prosthetic connection to an equi-gingival level, therefore facilitating all subsequent processes (securing the impression copings, validation of the passive fit of the restorations, seating of the restorations).

- Correcting the angulation of the implant. It is common to tilt the implant deliberately at an angle to optimize the antero-posterior (AP) spread.

Often, during surgery, the treating team may choose a specific set of transmucosal or SRA abutments, as these vary in height and angulation (Straight, 17 degrees, and 30 degrees), then fabricate the provisional restoration and wait for the implants to be fully osseointegrated prior to the fabrication of the definitive prosthesis.

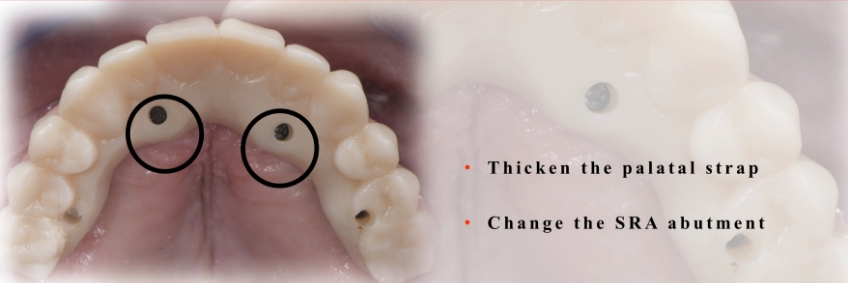

Usually, straight SRA abutments are used with anterior implants when they are parallel, but it is not uncommon during the prosthetic phase of treatment for the restorative dentist to realize that the position of the screw access hole could be optimized by changing the angulation of the SRA abutments. Ideally, the treating team aims to have the access holes coming out of the cingulum in anterior implants, and the center of the occlusal area in posterior implants.

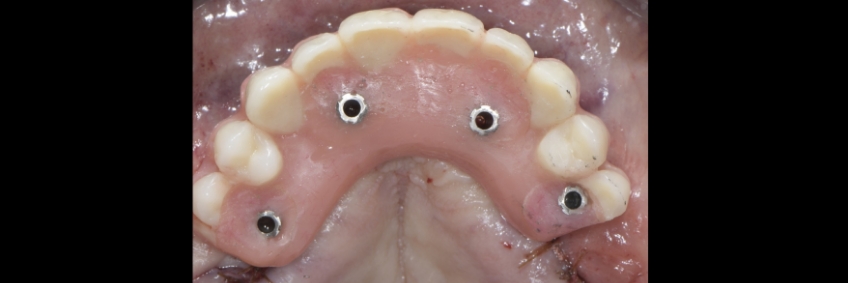

This visual essay shows, through a series of images, the fabrication of a maxillary implant-supported fixed dental prosthesis where the SRA abutments of the anterior implants were changed to optimize the prosthetic design of the definitive implant-supported fixed dental prosthesis.

If we decide to alter the angulation of the SRA abutments, we can position the access hole more anteriorly, thus increasing the palatal thickness and improving the biomechanics and hygiene access.

In this visual essay, we have outlined the steps in the fabrication of a maxillary full arch implant-supported prosthesis solution where the SRA abutment needs to be changed because the orientation of the screw access hole in the provisional restorations seems too palatal from an ideal position, thereby underlining the importance of analyzing these aspects during the provisional phase and correcting the angulation of them in order to provide a more ideal design and increase the long term predictability of the prosthetics.

Ricardo Mitrani, D.D.S., M.S.D., is a member of Spear Resident Faculty.

Comments

December 26th, 2022

December 26th, 2022