Fully Guided Implant Placement and Definitive Restoration with CEREC Complete Digital Workflow

By Ricardo Mitrani on February 12, 2020 | commentsTechnology has advanced rapidly and utilizing new digital workflows allows us to design surgical guides and fabricate them chairside with in-house milling or 3D printing.

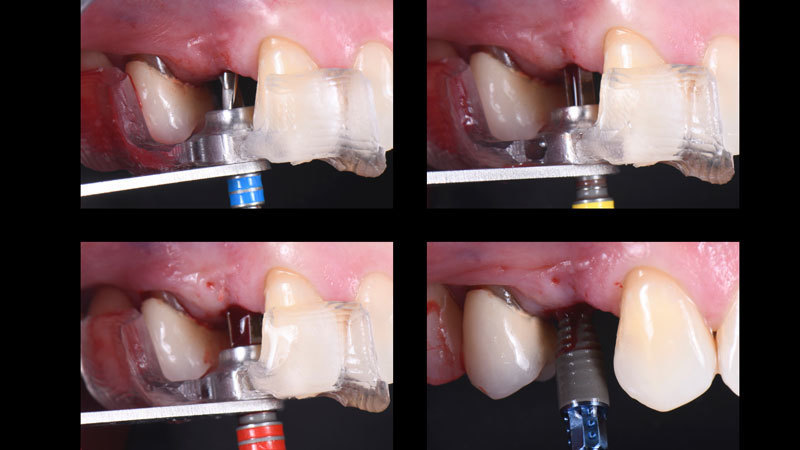

Surgical procedures have become less invasive and quicker, resulting in less patient morbidity and fewer complications. The production of this surgical guide is done by merging the information taken from the Galileos in DICOM format and the soft tissue and teeth information taken from the CEREC in SSI format.

This information is superimposed in the software and utilized to design a digital wax-up and virtual implant position. The guide is designed, and the information is transferred back to CEREC and milled from a CEREC Guide Bloc on a CEREC MC XL.

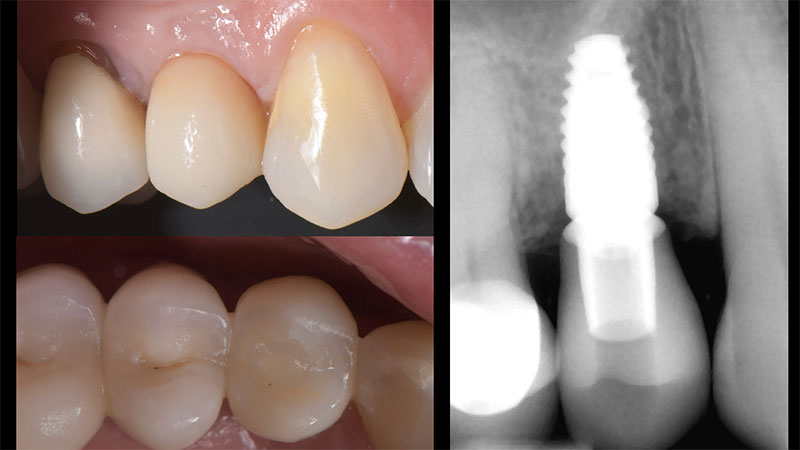

This visual essay will walk the reader through a fully guided implant placement and definitive restoration workflow utilizing the CEREC system.

When looking at the versatility of the CEREC system, there is an efficient digital workflow that allows you to three dimensionally predict the final placement of a single-tooth implant and forecast the esthetics of the final restoration to fabricate the surgical guide, provisional and definitive restoration without the need of a conventional impression.

Ricardo Mitrani, D.D.S., M.S.D., is a member of Spear Resident Faculty.